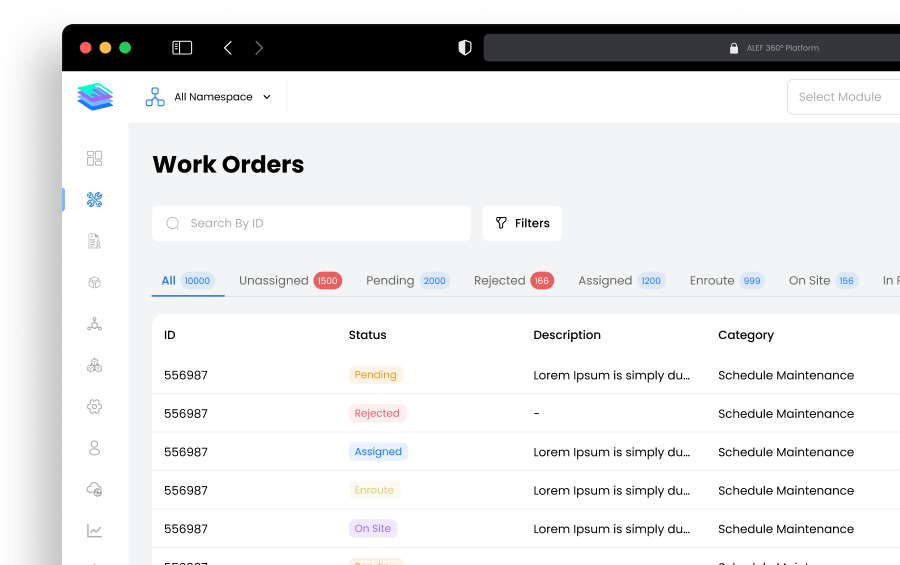

Level Monitoring

Rooted in the prowess of the Internet of Things (IoT), our level monitoring solution bring you unfiltered, real-time insights. We transform level monitoring from a reactive process into a proactive strategy – helping you achieve precision, safety, and productivity.

What is Level Monitoring?

- Level monitoring is the process of measuring and tracking the volume or presence of substances, such as liquids or solids, in a given space or container.

- Employing sensor-based technologies, it provides real-time data for analysis, enabling efficient process control and resource management.

Challenges

Resource Wastage

Without proper monitoring, overfilling or underfilling can occur, leading to resource wastage.

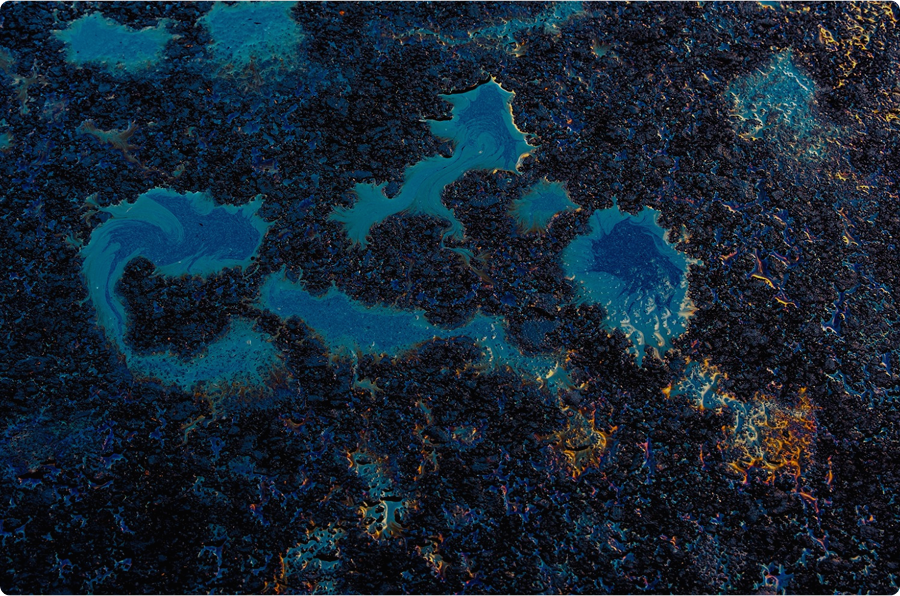

Environmental Risks

Overfills in tanks can lead to spills, posing potential safety hazards and environmental risks.

Inconsistent Product Quality

In industries like food & beverage and pharmaceuticals, improper level control can result in inconsistent product quality.

Level Monitoring Use Cases & Benefits

Manufacturing

Level monitoring is crucial in manufacturing processes where the precise measurement of liquids or solids is required for quality control.

Oil & Gas

In the oil and gas industry, level monitoring is used to avoid overfills in storage tanks, ensuring safety and environmental compliance.

Water Management

For utilities and water management, level monitoring can help track water usage, detect leaks, and manage resources more efficiently.

Food & Beverage

In the food and beverage industry, level monitoring is used to maintain the right quantities in mixtures and solutions, ensuring consistent product quality.